C.R. Bard

C.R. Bard specializes in vascular, urology, surgery and oncology devices. In 2017, it became a wholly owned subsidiary of Becton, Dickinson & Company (BD). The company manufactures thousands of medical devices and sells them worldwide.

In April 2017, medical technology company Becton, Dickinson & Co., better known simply as BD, announced it had acquired C.R. Bard, Inc. (branded now as Bard) for $24 billion. At the time of the acquisition, the companies had a combined $16 billion in annual revenue and 65,000 employees.

Based in Murray Hill, New Jersey, Bard reported $531 million in net income on $3.7 billion in revenue for 2016 before the BD acquisition. The company manufactures about 15,000 products.

Founded by a clothing importer, Bard grew into a manufacturer with a particular focus on life-saving devices for cardiovascular and cancer treatments.

But along the way, the company also pleaded guilty to criminal charges stemming from medical fraud and has been accused of selling defective devices that have killed patients or caused serious complications.

It has paid millions in settlements and jury verdicts to states and injured individuals.

Device Manufacturer Bard Began as an Importer and Distributor

Charles Russell Bard owned a New York business importing French scarves in the early 20th century. He suffered from urinary discomfort as a result of tuberculosis and began using a European “cure-all” called Gomenol that eased the pain. In 1907, Bard began importing and distributing Gomenol in the U.S., marking his company’s entrance into the medical industry. He landed exclusive rights to distribute a French-made urethral catheter that same year.

In 1915, Bard partnered with Morgan Parker, forming the partnership Bard-Parker to distribute a new type of scalpel. Demand for the domestically produced surgical tool surged as World War I cut off the supply of European scalpels to the U.S. In 1923, Parker bought Bard’s rights to the company. Bard-Parker would later become part of BD – the company that acquired the rest of Bard’s legacy in 2017.

In 1923, C.R. Bard incorporated to distribute catheters and other urology-related medical devices – largely from French suppliers. For the next 40 years, Bard’s business model would revolve primarily around distribution, either of products developed and manufactured by other companies or to Bard’s specifications.

Charles Bard died in 1934 after selling the company to two of his employees. In the 1930s, C.R. Bard distributed the Foley catheter, developed by Davol Rubber Company. The catheter became popular for post-surgery uses and was the best-selling product for most of Bard’s history.

Bard Bolsters Manufacturing in Post-War Years

With more than 80 percent of its pre-war inventory imported and American suppliers bypassing Bard to sell directly to the military during World War II, Bard was hard-pressed to meet demands from its civilian customers during the war.

But the post-war years were a boom time for the company as more urologists opened practices and developed new medical procedures.

-

1948

Bard’s sales topped $1 million for the first time. By the 1950s, Bard was no longer distributing imported devices; its entire catalogue of products was manufactured in the U.S.

-

1957

Bard began selling its products in pre-sterilized packaging, saving time and expenses for the hospitals and physicians who were Bard customers. Originally contracting with an outside laboratory to handle the packaging, Bard quickly moved to create its own facility.

-

1964

Bard established its first in-house manufacturing plant – producing medical plastic tubing. By 1969, the company owned 14 factories and manufactured 75 percent of the devices in its 6,000 product catalogue.

-

1963

The company expanded distribution to the United Kingdom and Canada. Bard also began acquiring other companies in the 1960s. By 1968, it had acquired USCI, manufacturer of the first intravenous heart catheter, along with two other companies that manufactured hospital supplies and equipment.

Acquisitions, Joint Ventures Fuel Bard’s Growth

Bard acquired 10 more medical-related companies during the 1970s, expanding the company’s reach into cardiology and surgical supplies. The company also launched joint ventures with companies in Japan and Denmark to market its products in Asia and Europe.

By 1976, Bard was manufacturing or distributing 13,000 products.

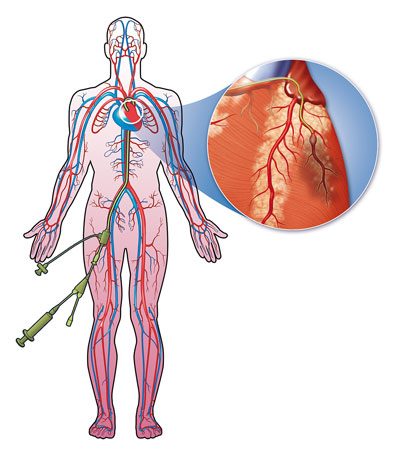

In 1979, Bard gained exclusive rights to manufacture and market the Gruntzig angioplasty catheter. Angioplasty is a less expensive and far less invasive alternative to open heart surgery for treating artery blockages. The procedure involves inserting an inflatable balloon at the blockage using a catheter. The balloon expands, pushing aside fatty deposits and restoring normal blood flow.

Bard’s rapid and expansive growth forced the company to rethink its structure in 1980. Bard dropped its centralized management approach and created divisions around its specific product lines. Bard acquired at least six more companies during the 1980s.

Bard Pleads Guilty to Criminal Charges over Heart Catheters

By the late 1980s, angioplasty and coronary catheter devices were among Bard’s best-selling devices. But the whole division would be gone in less than 10 years.

In 1989 and 1990, Bard began recalling defective heart catheters. The balloons in the tips of the angioplasty devices were supposed to inflate to relieve blockage in arteries. But some broke apart in patients, requiring emergency surgery. One device failed to deflate, killing the patient.

The U.S. Food and Drug Administration (FDA) and Department of Justice (DOJ) launched a joint investigation into the company and the DOJ returned criminal indictments against Bard and six of its leaders in 1993.

The indictment against the company claimed Bard was aware of problems with its catheter, but didn’t report them to the FDA. It also said that the company lied to the FDA about animal tests to get a catheter model to market and conducted human tests of another catheter that did not have FDA approval.

“For a company to engage in a pattern of using unsuspecting patients as guinea pigs and operating rooms as laboratories for unapproved products shows a blatant disregard for the health and safety of the patients who literally entrusted their lives to the company’s products,” FDA Commissioner David Kessler said at the time.

In December 1993, Bard pleaded guilty in federal court to 391 criminal charges that involved accusations of selling defective heart catheters, hiding problems with the catheters from the FDA and conducting illegal experiments on humans.

In a settlement with the FDA and DOJ, Bard agreed to pay $61 million. Half would be for a criminal fine and half for a civil liability settlement. Six Bard executives were also prosecuted in separate trials. Three were acquitted and three others were each sentenced to 18 months in prison for their roles in the catheter episode.

Bard’s coronary catheter business never fully recovered during the 1990s. In 1998, the company sold it to Arterial Vascular Engineering Inc. for $550 million. Medtronic purchased Arterial Vascular later that year for $3.7 billion.

New Directions Bring New Problems for Bard

By 2000, Bard had sold off most of the rest of its heart-related device manufacturing. New leadership consolidated the company around vascular, urology, cancer-related and surgical specialty devices.

Early in the new millennium, the company also experienced expensive litigation over complications from some of their products and another investigation from the DOJ.

In 2001, Bard acquired Surgical Sense, Inc., which made the Kugel line of hernia surgical mesh. This acquisition built onto Bard’s surgical specialty sector.

Bard issued a recall for tens of thousands of the Kugel mesh devices and widened the recall in 2006 and 2007. Some of the patches broke and perforated bowels. In 2011, Bard offered to pay $184 million to resolve more than 3,000 lawsuits filed over injuries from the patches.

Another legal issue for Bard involved its brachytherapy seeds. Brachytherapy is a form of radiation treatment that is used to treat prostate cancer. The seeds are radioactive implants that are placed directly in the patient’s tissue. Bard sold both the seeds and the devices to implant them.

In 2012, Bard agreed to pay the federal government $48.26 million to resolve charges it violated two federal laws. The DOJ claimed that between 1998 and 2006, the company paid illegal kickbacks to doctors and other customers to buy Bard’s brachytherapy seeds. Hospitals then filed Medicare claims to pay for the seeds.

The DOJ said the actions violated both the federal Anti-Kickback Statue and the federal False Claims Act. The U.S. attorney argued that because the kickbacks were illegal, Bard was then liable for the Medicare claims that hospitals filed for the seeds.

Bard Transvaginal Mesh Results in Serious Medical Complications

Transvaginal mesh (TVM) would create even more problems for Bard. TVM was introduced in the 1990s to treat incontinence and repair pelvic organ prolapse (POP). POP is a weakening or stretching of tissue holding pelvic organs in place. As the tissue deteriorates, the organs can collapse into the vagina, causing organ perforation.

The first TVM to receive FDA approval was Boston Scientific’s ProteGen in 1996. Boston Scientific would withdraw the mesh from the market in 1999, just three years after it received FDA approval. A study had found half of all women implanted with it developed serious health complications.

But other companies sought approval of their own versions of TVM through the FDA’s 510k process. This allows quicker approval of a device if the manufacturer shows it is substantially similar to one already approved. So, despite its problems, ProteGen became a standard other companies pointed to in seeking approval for their own versions.

- Avaulta

- Collagen Matrix

- Pelvicol Acellular

- Pelvilace

- Pelvisoft BioMesh

- Pelvitex

In 2016, the FDA strengthened requirements for TVM, including listing all versions as Class III, or “high-risk,” medical devices.

News Reports Associate Bard IVC Filters with 27 Patient Deaths

In 2015, NBC News ran a series of reports claiming Bard officials were aware of potentially lethal problems with some of the company’s inferior vena cava (IVC) filters.

IVC filters are cage-like devices implanted in the inferior vena cava, the largest vein in the body. They are supposed to catch blood clots before they can reach the lungs or heart.

The network reported Bard’s Recovery IVC filter had been associated with 27 deaths when the devices broke or migrated through the body. The news reports claimed internal Bard documents showed the company was aware of the problems but instead of recalling the devices, tried to manage the crisis to maintain stock prices.

Bard eventually replaced the Recovery in 2005 with similar products – the G2 and later with the G2 Express.

Bard Grows As It Seeks a Buyer

As early as 2001, Bard was prepared to be acquired by a larger company. Bard was a medium-sized medical device manufacturer in an industry that was quickly consolidating around fewer and fewer big players.

When the deal fell through, Bard moved forward with more acquisitions of its own. It spent more than $1.8 billion acquiring 15 more companies by 2015, making Bard more attractive as an acquisition target itself.

In April 2017, BD agreed to acquire Bard in a $24 billion deal expected to be finalized in the fall of 2017, pending regulatory approval. Bard shareholders would control about 15 percent of the combined company.

BD saw the acquisition as a way to offer products reducing the chance of hospital-acquired infections. In a presentation to investors, BD projected growth for the combined company at 5 to 6 percent through 2020.

Bard, founded 110 years earlier by a clothing importer, will become a new BD division, renamed BD International.

Lawsuits, Settlements and Verdicts

Bard still faces active product liability lawsuits for its hernia mesh and IVC filter devices, and it settled the majority of its transvaginal mesh lawsuits in 2015. In 2023, patients who said they were harmed by the Bard PowerPort filed the latest lawsuits against the company.

In BD’s 2019 annual report, the company said it set aside $2.5 billion for product liability. BD said “it was a defendant in various product liability matters in which the plaintiffs allege a wide variety of claims associated with the use of certain Company devices.”

In addition to lawsuits stemming from Bard products, BD faces Alaris Systems lawsuits stemming from recalls for defective software, hardware and other issues that led to serious injuries and at least one death.

Bard PowerPort

As of September 2023, BD and Bard faced 50 PowerPort lawsuits in multidistrict litigation in Arizona. The judge overseeing the Bard IVC filter MDL, David G. Campbell, will also be presiding over the PowerPort litigation. Plaintiffs claimed that defective design caused serious Bard PowerPort side effects such as infections and blood clots.

At the time that the cases were consolidated in the MDL, Bard had filed several motions to dismiss. In an order dated Sept. 19, 2023, Judge Campbell denied all pending motions to dismiss without prejudice. This litigation is in the early stages and plans for discovery and other procedures are still being proposed.

Hernia Mesh

In October 2020, Bard faced 9,394 federal lawsuits in multidistrict litigation in Ohio for its polypropylene hernia mesh products. As of March 2021, that number has increased to 11,145.

People who filed hernia mesh lawsuits claim the implants caused infections, organ perforation, adhesions, hernia recurrence, intestinal blockage, mesh migration and other injuries. There haven’t been any jury verdicts or settlements in these cases yet.

The first bellwether trial is scheduled for April 2021 after it was postponed several times because of the COVID-19 pandemic. A second trial is tentatively set for some time in summer 2021.

IVC Filters

The device maker faces 1,322 federal IVC filter lawsuits in Arizona federal court as of March 2021. In March 2018, a jury awarded Sherr-Una Booker $3.6 million in the first Bard trial.

Since then, Bard has won three bellwether trials and settled a fourth for an undisclosed amount.

Transvaginal Mesh

At one time, Bard faced more than 15,000 transvaginal mesh lawsuits. After losing two verdicts totaling $5.6 million, Bard settled a third lawsuit for $2 million.

In 2014, the company agreed to settle another 500 for $21 million. The company settled almost all remaining cases in 2015 for $200 million.

In September 2020, Bard agreed to settle lawsuits with 48 states related to marketing of its pelvic mesh products for $60 million.

In March 2021, a New Jersey appeals court threw out a $68 million verdict against Bard in Mary McGinnis’s case.

Calling this number connects you with a Drugwatch.com representative. We will direct you to one of our trusted legal partners for a free case review.

Drugwatch.com's trusted legal partners support the organization's mission to keep people safe from dangerous drugs and medical devices. For more information, visit our partners page.